Inbound Logistics Solutions

Inbound Logistics Solutions

WHAT IS INBOUND LOGISTICS?

Inbound logistics refers to the set of processes designed for the efficiency of the logistic supply chain, from the entrance point inside the distribution center up to the acceptance and storage into the DC itself. In this page we will specifically address the topic of inbound logistics solutions, starting from the definition of the main processes involved up to each related product options.

DATALOGIC’S INBOUND LOGISTICS SOLUTIONS

We will address inbound logistics solutions and processes as divided into three specific areas:

- Forklifting

- Tracking, dimensioning, and weighing

- Pallet acceptance and check

So, if you are looking for inbound logistics services, you have landed in the right place as we will guide you through the main options currently available within our dedicated portfolio.

FORKLIFT SOLUTIONS

Forklifting constitutes a common yet fundamental activity of distribution centers to be accurately monitored by transportation management. Among the logistics solutions for forklifting are AutoID devices used to exponentially increase forklifts operativity. The PowerScan combined with the Rhino II, and a Matrix 320 between the fork, is the complete forklift solution for fast and seamless data capture.

Forklift Trucks (FLT) can be found in large numbers throughout distribution centers today. They offer a lot more than simple manual handling of pallets. Considering that the average size of a warehouse is 18,000 square meters, over 100,000 products can be easily stored on approximately 15,000 pallets. A fleet of say 10 FLTs will be required to handle 1,000 pallets per day. Given that FLTs are manned vehicles, it will be almost impossible to find specific pallets easily and in the shortest space of time. Briefly, without a forklift solution that includes some level of connectivity, labor costs would rise dramatically.

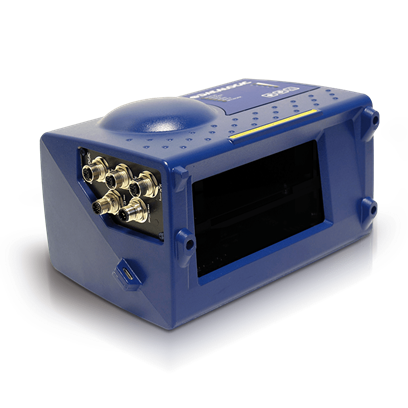

Inventory management needs streamlined operations to answer consumer’s demand in real time to preserve the integrity of the orders flow. For increased productivity, a modern-day FLT needs robust inbound logistics solutions like a Vehicle Mount Terminal, such as the Rhino II – a powerful Vehicle Mount Terminal device equipped with an Android™ based interface, wirelessly connected to the warehouse management system or ERP. The FLT acts as a self-contained Local Area Network (LAN), where several connected devices can be used to read barcodes either manually or in a totally automated fashion.

At any point along the supply chain, work instructions are seamlessly delivered to the driver via the Rhino II, providing precise details of where pallets are located. The driver, knowing where to go, locates the correct pallet, scans the barcode either manually with a PowerScan XLR scanner, or with the aid of a mounted Stationary Industrial Scanner such as the Matrix 320 scanner, which can easily be mounted between the forks. Inventory levels can be perfectly tracked for shipping and receiving, put away and storage, or order fulfillment. Forklift solutions, involving the use of correct equipment for capturing barcodes and images, are critical in operations where a wide field of view is required and when barcodes are damaged or behind external wrapping.

INBOUND LOGISTICS PROCESSES: TRACKING, DIMENSIONING, AND WEIGHING SOLUTIONS

Among the strategic inbound logistics processes, tracking, dimensioning, and weighing solutions represent crucial steps in inventory management. Unloaded parcels, from trucks, are dimensioned and weighed; thousands of parcels are automatically handled and sorted by size and weight.

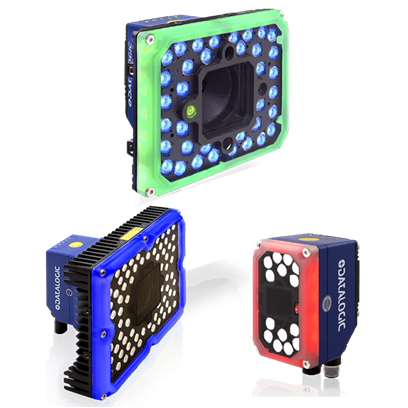

When parcels arrive at a distribution center, telescopic conveyor systems are sometimes used to retrieve them directly from the delivery vans, trucks, trailers, or airplane containers. It is important to ascertain that the parcels meet with expectations by automatically capturing barcode data, high resolution images, dimensions, and weight and directly check if these data match into the warehouse management system. Tracking, dimensioning, and weighing solutions ensure you have everything you need to satisfy e-commerce order fulfillment requirements: validation that correct goods have been delivered and quality checked, so that they can be taken to the relevant storage location, all with complete traceability. In addition, captured data can be used for quality checks or storage optimization. The DM3610 dimensioner, in combination with the AV900 high performance 2D reader, is the perfect inbound logistics solution for this case scenario.

Datalogic already has the perfect set of modular tracking, dimensioning, and weighing solutions, packed with easy to integrate devices to help ensure the highest speed e-commerce demands are met. Firstly, the DM3610 is a high performance, overhead dimensioning unit for automatically measuring the volume, the length, width, and height of packages as they are transported on a conveyor. Secondly, the AV900 is a high-performance industrial camera that reads and recognizes an extensive range of barcodes and captures high-resolution images of parcels easily, thanks to its large field of view and class-leading 9MP sensor. The combination of these two products brings the much-needed extended capability required by the busiest of distribution centers without rising labor costs. Automated processes help to streamline operations and improve accuracy, eliminating human errors that may impact the receiving and put away processes, as well as the cash flow.

PALLET ACCEPTANCE AND CHECK SOLUTIONS

During pallet acceptance and check, operators make sure that received goods match with the purchase order and the expected quality standard. The Skorpio X5 mobile computer is the perfect logistics solution device for the warehouse management, with its wide and bright display, and the capability to take pictures for recording any quality issues in real time.

Any goods being transported along the supply chain to a distribution center usually come packed in pallets. When they arrive, their dimensions, weight, and product codes are checked so that quality compliance and complete traceability are guaranteed for inventory management. Furthermore, they also need to be checked against expected purchase orders in the inbound area. Datalogic provides a powerful range of rugged mobile computer devices as pallet acceptance and check solutions, such as the state-of-the-art Skorpio X5 device, for seamless integration with warehouse management systems.

It is important to have long-range scanning capability, avoiding the need to pace up and down aisles, and even capture data from a moving forklift truck. Many goods experience some level of wear and tear during transportation, and barcodes can become harder to read through damage or by being obscured by semi-opaque wrapping. It is therefore important to make use of high capability handheld devices to not only capture product information easily and on the first scan, but also to capture high resolution images for verifying any unforeseen quality issues. The Skorpio X5 Android™ rugged mobile computer is designed to provide greater efficiency to sensitive inbound logistics operations like pallet acceptance and check, thanks to instantaneous feedback from the connected enterprise.

FORKLIFT SOLUTIONS: MANUAL AND AUTOMATED

Forklifts are used in many areas of a Distribution Center: when equipped with AutoID devices, they increase productivity enormously. The PowerScan combined with the Rhino II VMT, and a Matrix 320 between the fork, is the complete solution for fast and seamless data capture.

Forklift Trucks (FLT) can be found in large numbers throughout Distribution Centers today. They offer a lot more than simple manual handling of pallets. Considering that the average size of a warehouse is 18,000 square meters, over 100,000 products can be easily stored on approximately 15,000 pallets. A fleet of say 10 FLTs will be required to handle 1000’s of pallets per day. Given that FLTs are manned vehicles, it will be almost impossible to find specific pallets easily and in in the shortest space of time without some level of connectivity.

Time is money, and streamlined operations need to fulfil consumer demand to receive their orders quickly. For increased productivity a modern-day FLT will be equipped with a Vehicle Mount Terminal, such as the Rhino II VMT - a powerful Android based device that is wirelessly connected to the warehouse management system or ERP. The FLT acts as a self-contained Local Area Network (LAN), where a number of connected devices can be used to read barcodes either manually or in a totally automated fashion.

Work instructions are seamlessly delivered to the driver via the Rhino II VMT, providing precise details of where pallets are located. The driver, knowing where to go, locates the correct pallet, scans the barcode either manually with PowerScan XLR scanner, or with the aid of a mounted Stationary Industrial Scanner such as the Matrix 320, which can easily be mounted between the forks. Inventory levels can be perfectly tracked for shipping and receiving, put away and storage, or order fulfilment. Using the correct equipment for capturing barcodes and images is critical in operations where a wide field of view is required and when barcodes are damaged or behind external wrapping.

TRACKING, DIMENSIONING, WEIGHTING

![]()

Unloaded parcels are dimensioned and weighted; thousands of parcels are automatically handled and classified based on dimensions and weight. The

When parcels arrive at a Distribution Center, telescopic conveyer systems are sometimes used to retrieve them directly from the delivery vans, trucks, trailers, or airplane containers (Unit Load Devices - ULD). It is important to ascertain that the parcels meet with expectations by automatically capturing barcode data, high resolution images, dimensions, and weight. You have everything you need to satisfy e-commerce order fulfilment requirements: validation that the correct goods have been delivered and quality checked so that they can be taken to the relevant storage location, all with complete traceability.captured data can be used for quality checks or storage optimization. The DM3610 in combination with the AV900 is the perfect solution.

Datalogic already has the perfect set of modular, and easy to integrate products to help ensure the highest speed e-commerce demands are met. Firstly, the DM3610 is a high performance, overhead dimensioning unit for automatically measuring the volume, the length, width, and height of packages as they are transported on a conveyor. Secondly, the AV900 is a high-performance industrial camera that reads and recognises an extensive range of barcodes and captures high -resolution images of parcels easily, thanks to its large field of view and class-leading 9MP sensor. The combination of these two products brings the much-needed extended capability required by the busiest of Distribution Centres. Automated processes help to streamline operations and improve accuracy, eliminating human errors that may impact the receiving and put away processes.

PALLET ACCEPTANCE AND CHECK

Received goods must match with the relevant purchase order: this is the main priority in the InBound area, together with quality checks; The Skorpio X5 is the perfect device, with its wide and bright display, and the capability to take pictures for recordingany quality issues.

Received goods must match with the relevant purchase order: this is the main priority in the InBound area, together with quality checks; The Skorpio X5 is the perfect device, with its wide and bright display, and the capability to take pictures for recordingany quality issues.

Any incoming goods to a Distribution Center, typically pallets, are first checked to ensure that they have the correct dimensions, weight, and product codes to ensure complete traceability. Furthermore, they also need to be checked against expected purchase orders in the inbound area. Datalogic provides a powerful range of rugged mobile computer devices such as the state-of-the-art Skorpio X5, for seamless integration with warehouse management systems.

It is important to have long-range scanning capability, avoiding the need to pace up and down aisles, and even capture data from a moving forklift truck. Many goods experience some level of wear and tear during transportation, and barcodes can become harder to read through damage or by being obscured by semi-opaque wrapping. It is therefore important to make use of high capability handheld devices to not only capture product information easily and on the first scan, but also to capture high resolution images for verifying any unforeseen quality issues. The Skorpio X5 is designed to provide greater efficiency to warehouse operations thanks to instantaneous feedback from the connected enterprise.