Inbound logistics (Receiving): solutions for item identification, dimensional checks, and verification of the printed & applied labels

Inbound logistics (Receiving): solutions for item identification, dimensional checks, and verification of the printed & applied labels

INBOUND LOGISTICS MANAGEMENT: ADVANCED SOLUTIONS FOR STREAMLINING RECEIVING PROCESSES

In the landscape of warehouse operations, inbound logistics management is as a crucial pillar in ensuring streamlined processes. It encompasses the entire gamut of activities responsible for the orderly flow of materials and products from suppliers to the warehouse. The efficiency of these operations has a major impact on the overall business, determining the speed and accuracy of service delivery and customer satisfaction. A key element of inbound logistics is the receiving process, where incoming materials are verified against the shipping manifest and then integrated into the Warehouse Management System (WMS). The effectiveness and accuracy of this phase are critical as they set the tone for subsequent processes such as storage, picking, packing, and shipping. Now we delve into innovative solutions for item identification, dimensional checks, and the verification of printed and applied labels, all of which are crucial in enhancing the receiving process.

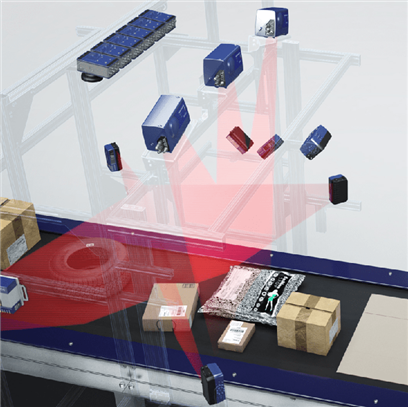

ITEM IDENTIFICATION: THE HEARTBEAT OF INBOUND LOGISTICS

Accurate item identification at the receiving dock is of paramount importance to effective inbound logistics management. Such processes are the foundation for precise inventory management and a key defense against out-of-stocks. To ensure accuracy and speed, most companies employ technology tools such as mobile computers and barcode scanners to provide fast and reliable item identification. As goods enter the warehouse, they are scanned and compared to the bill of landing to confirm receipt and register the goods in the inventory management system. This initial scan is a critical step that informs the WMS of inventory changes and helps plan material storage.

In addition to traditional barcode scanners, cutting-edge solutions include the use of Radio Frequency Identification (RFID) technology to identify items. Unlike barcode scanning, which requires a line of sight, RFID tags can be read when in proximity and even through packaging materials, making the process much faster and more efficient. With the ability to scan multiple items at once, RFID technology significantly reduces labor costs and time, improving the overall efficiency of the receiving process.

DIMENSIONAL CHECKS AND ANALYSIS

Beyond item identification, dimensional checks are another vital step in inbound logistics. This process involves measuring incoming goods’ size and weight, ensuring they are correctly categorized for storage and handling. In addition, dimensional checks are decisive for the efficient use of space within the warehouse, enabling storage planning and avoiding potential congestion.

Several technologies support dimensional checks. Automated dimensioners, for example, swiftly capture the size and weight metrics of incoming goods and feed this information directly into the WMS. Furthermore, advanced dimensional analysis, such as 3D scanners, has opened up new avenues. Beyond just taking measurements, these tools can identify irregularities in packaging, helping to improve quality control and early detection of potential issues.

VERIFICATION OF PRINTED AND APPLIED LABELS: THE KEY TO ACCURACY

The significant role of printed and applied labels in efficient inbound logistics operations cannot be overstated. These labels carry essential information such as the item name, SKU, and price, among other details that guide subsequent stages of picking, packing, and shipping.

Label verification tools, equipped with advanced scanning and decoding technologies, are used to cross-check the accuracy and readability of printed labels. These systems compare the decoded information from the label with the recorded data in the system, flagging any discrepancies immediately. This instantaneous error detection allows for real-time correction, preventing mislabeling, misdelivery, and other related errors to ensure smooth operations.

In the age of artificial intelligence, machine learning algorithms are now being incorporated into these verification systems. These methods are designed to learn from previous errors and improve accuracy over time, continually refining the label verification process.

CONCLUSION

Incorporating advanced item identification, dimensional checks, and label verification solutions can significantly improve the efficiency of the receiving process in inbound logistics management. Using these technologies not only minimizes errors but also facilitates real-time inventory updates, reducing the risk of out-of-stocks and ensuring that the right products reach the right destination at the right time. Industry leaders like Datalogic are at the forefront of this transformation, providing both manual and automated solutions to optimize shipping and receiving operations. As technology continues to evolve, we can expect the emergence of more refined and sophisticated solutions that will further streamline and enhance the intricacies of inbound logistics.

Products and Solutions

Video Gallery

Datalogic Solutions for Distribution Centers

Iper has chosen Datalogic devices for the new sales outlet in Arese