High-Tech Solutions for Warehouse Efficiency: The Role of Mobile Computers and Handheld Scanners in Sorting and Picking

High-Tech Solutions for Warehouse Efficiency: The Role of Mobile Computers and Handheld Scanners in Sorting and Picking

The modern logistics industry is a complex field where accuracy is paramount. Sorting and picking is at the heart of this process, ensuring customer orders are fulfilled as efficiently and precisely as possible. While e-commerce continues to grow and shipping volumes increase, warehouses relyon advanced mobile computers and handheld scanners to maintain consistency in fulfilling all orders that leave their facilities.

THE IMPORTANCE OF SORTING AND PICKING IN THE ORDER PICKING PROCESS

The order-picking process is the backbone of any warehouse operation. It involves retrieving products from their pick location and preparing them for shipment to satisfy customer orders. This process must be accurate and efficient, as errors can cause significant losses or dissatisfied customers.

BACTH PICKING AND MULTI-ORDER EFFICIENCY

Batch picking is one of the most efficient picking methods, because it allows multiple orders to be picked simultaneously. Warehouses can handle several orders at a time by grouping similar items or those located in the same pick area. This approach reduces travel time within the warehouse, resulting in faster and more smooth order fulfillment.

THE ROLE OF MOBILE COMPUTERS AND HANDHELD SCANNERS IN WAREHOUSE MANAGEMENT

In the fast-paced warehouse management landscape, mobile computers and handheld scanners are essential tools. They streamline the order fulfillment process by providing up-to-the-minute inventory information, pick locations, and the pick order status. Integrating this technology means that order pickers receive the most precise updates, minimizing errors and increasing productivity.

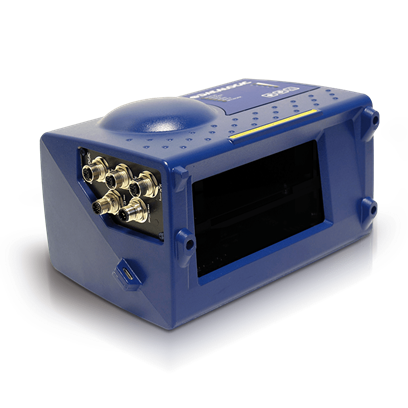

DATALOGIC DIMENSION WEIGH SCAN SYSTEMS: THE FUTURE OF PICKING SYSTEMS

Today’s shipping and freight cost management is based on the weight and volume of a shipment. Datalogic Dimension Weigh Scan systems provide a comprehensive solution with dimensioners, scales, and barcode readers that ensure authorized package profiles. This system combines barcode, weight, and dimensional data into a single message. This integrated approach enables efficient sorting and verification, lowering shipping costs and increasing customer satisfaction.

ADVANCED PICKING METHODS: WAVE PICKING AND ZONE PICKING

Two other advanced picking methods further improve the process. Wave picking allows order pickers to collect multiple items from different areas in a warehouse at a given time, while zone picking assigns specific zones to each picker. Both approaches minimize travel time and optimize the order fulfillment process.

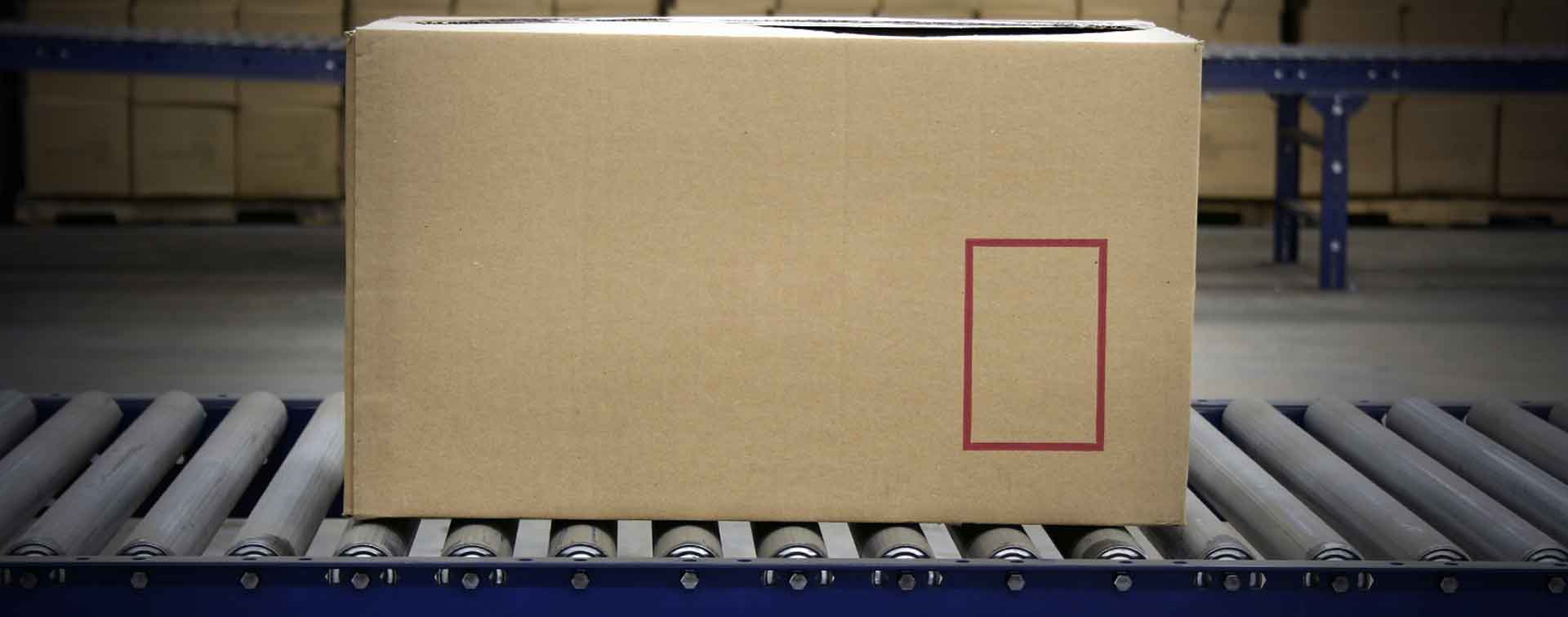

INTEGRATION WITH CONVEYOR AND SORTING SYSTEMS

After picking, the sorted items are directed to their respective shipping areas. Advanced conveyor systems, coupled with an efficient sorting system, ensure correct item grouping and transport. These systems further reduce the risk of errors and secure timely and intact delivery of each package.

CONCLUSION

The seamless integration of high-tech mobile computers, handheld scanners, and advanced picking and sorting systems is changing the game in warehouse management. These tools and techniques place accuracy and efficiency at the forefront, guaranteeing customer orders are fulfilled with the precision and care demanded by today's marketplace. As the logistics industry continues to expand and evolve, adopting these technologies will be essential to ensuring operational success and customer satisfaction.